The Ultimate Guide: How to Remove a Screw with No Head Without an Extractor

Stripped screws are the bane of any DIY enthusiast’s existence. You’re working on a project, everything’s going smoothly, and then – snap! The head of the screw shears off, leaving you with a headless screw embedded in your material. The frustration is real. You might think you need a specialized screw extractor tool to solve this problem, but what if you don’t have one? Don’t panic! This comprehensive guide will walk you through several methods on how to remove a screw with no head without an extractor. These techniques are designed for various situations and require tools you likely already have in your toolbox. We’ll explore everything from simple rubber band tricks to more involved approaches using rotary tools. Let’s dive in and reclaim your project from the clutches of that pesky headless screw.

Understanding the Problem: Why Screws Break

Before we jump into solutions, it’s helpful to understand why screw heads break in the first place. Several factors can contribute to this unfortunate event:

- Over-Tightening: This is the most common culprit. Applying too much torque, especially with power tools, can easily shear off the screw head.

- Corrosion: Rust weakens the metal, making the screw more susceptible to breakage.

- Improper Screw Size: Using a screw that’s too small for the job can cause it to snap under pressure.

- Low-Quality Screws: Cheaper screws are often made from inferior materials, making them more prone to failure.

- Improper Driver Bit: Using the wrong size or type of screwdriver bit can strip the screw head, making it harder to grip and increasing the risk of breakage.

Knowing these causes can help you prevent future screw head casualties.

Tried and True Methods: Removing Headless Screws Without Extractors

Now, let’s get to the heart of the matter: how to remove a screw with no head without an extractor. Here are several methods, ranked from simplest to most involved, along with step-by-step instructions and safety tips.

The Rubber Band Trick

This method works best for screws that are not completely stripped or seized. It relies on creating extra friction between the screwdriver and the remaining screw shaft.

- Gather Your Materials: You’ll need a wide rubber band (like the kind used for produce) and a screwdriver that fits snugly in the screw’s hole.

- Place the Rubber Band: Place the rubber band over the stripped screw shaft.

- Insert the Screwdriver: Push the screwdriver through the rubber band and into the screw. The rubber band should fill the gap between the screwdriver and the screw.

- Apply Pressure and Turn: Apply firm, even pressure while slowly turning the screwdriver counterclockwise (to loosen). The rubber band should provide enough grip to turn the screw.

Pro Tip: If the rubber band breaks, try folding it over for extra thickness.

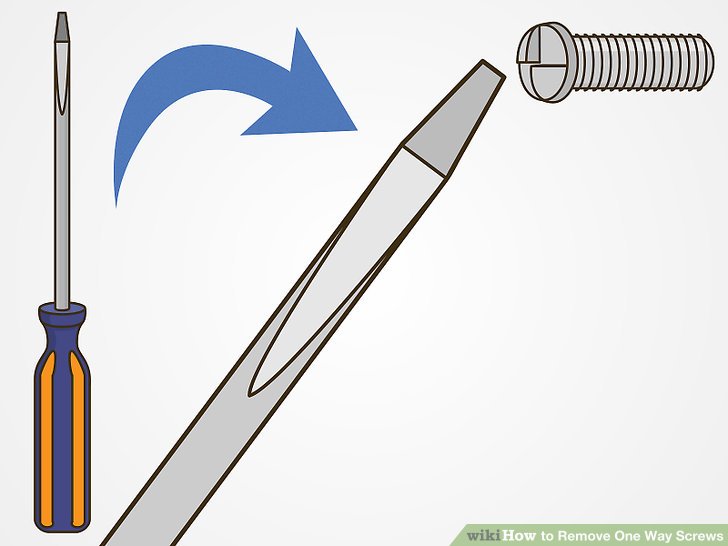

The Screwdriver and Hammer Technique

This method is suitable for screws that are slightly more stubborn. The hammering helps to create a new groove in the screw shaft.

- Gather Your Materials: You’ll need a flat-head screwdriver, a hammer, and safety glasses.

- Create a Notch: Carefully position the flat-head screwdriver on the edge of the screw shaft.

- Tap with the Hammer: Gently tap the screwdriver with the hammer to create a small notch in the screw shaft. This will give the screwdriver something to grip onto.

- Turn the Screw: Place the screwdriver in the notch and turn counterclockwise to loosen the screw.

Safety First: Always wear safety glasses when hammering to protect your eyes from flying debris.

The Pliers or Vise-Grip Approach

If enough of the screw shaft is exposed, you can use pliers or vise-grips to grab onto it and turn it out.

- Gather Your Materials: You’ll need a pair of pliers or vise-grips.

- Grip the Screw: Firmly grip the exposed screw shaft with the pliers or vise-grips.

- Turn Counterclockwise: Turn the pliers or vise-grips counterclockwise to loosen and remove the screw.

Important: Be careful not to damage the surrounding material when using pliers or vise-grips.

Creating a New Head with a Rotary Tool

This method requires a rotary tool (like a Dremel) and a cutting wheel. It involves creating a slot in the screw shaft that you can then use with a flat-head screwdriver.

- Gather Your Materials: You’ll need a rotary tool, a cutting wheel, safety glasses, and a flat-head screwdriver.

- Create a Slot: Carefully use the rotary tool and cutting wheel to create a slot across the top of the screw shaft. Make sure the slot is wide and deep enough to accommodate the flat-head screwdriver.

- Remove the Screw: Insert the flat-head screwdriver into the newly created slot and turn counterclockwise to remove the screw.

Safety First: Always wear safety glasses when using a rotary tool. Be careful not to overheat the screw, as this can make it even harder to remove. [See also: Best Rotary Tool Accessories]

Using Super Glue or Epoxy

This method involves gluing a sacrificial object (like an old screwdriver bit or a metal rod) to the screw shaft, allowing you to get a grip and turn it out.

- Gather Your Materials: You’ll need super glue or epoxy, a sacrificial object (screwdriver bit, metal rod, etc.), and a pair of pliers or vise-grips.

- Apply Glue: Apply a small amount of super glue or epoxy to the top of the screw shaft and to the sacrificial object.

- Bond the Objects: Carefully position the sacrificial object on top of the screw shaft and hold it in place until the glue or epoxy has set completely. This may take several minutes or even hours, depending on the adhesive used.

- Remove the Screw: Once the adhesive has cured, use pliers or vise-grips to grip the sacrificial object and turn counterclockwise to remove the screw.

Important: Make sure the adhesive is completely cured before attempting to remove the screw. Using epoxy will provide a stronger bond than super glue.

Heat It Up!

Applying heat can help to loosen corroded or seized screws. Heat expands the metal, which can break the bond between the screw and the surrounding material. This is also a good tip for how to remove a screw with no head without an extractor.

- Gather Your Materials: You’ll need a heat gun or soldering iron, and a pair of pliers or vise-grips.

- Apply Heat: Apply heat to the screw shaft for several minutes. Be careful not to overheat the surrounding material.

- Remove the Screw: Use pliers or vise-grips to grip the screw shaft and turn counterclockwise to remove the screw.

Safety First: Be careful when using a heat gun or soldering iron. Wear gloves to protect your hands from the heat. Do not use this method near flammable materials.

Preventing Future Screw Head Breakage

Now that you know how to remove a screw with no head without an extractor, let’s talk about prevention. Here are some tips to help you avoid this problem in the future:

- Use the Right Size Screwdriver: Make sure your screwdriver bit fits snugly in the screw head. A loose fit can strip the head and increase the risk of breakage.

- Apply Even Pressure: Apply firm, even pressure when turning the screw. Avoid tilting the screwdriver, as this can damage the screw head.

- Avoid Over-Tightening: Use a torque wrench to avoid over-tightening screws, especially when working with delicate materials.

- Use High-Quality Screws: Invest in high-quality screws made from durable materials.

- Lubricate Screws: Apply a small amount of lubricant (like WD-40) to screws before inserting them, especially when working with wood or metal.

- Pre-Drill Pilot Holes: When working with wood, pre-drill pilot holes to prevent the wood from splitting and to make it easier to insert the screws.

When to Call a Professional

While these methods can be effective, there are times when it’s best to call a professional. If the screw is deeply embedded, severely corroded, or located in a delicate or inaccessible area, it’s best to consult with a handyman or mechanic. They have the tools and expertise to remove the screw without causing further damage. Knowing how to remove a screw with no head without an extractor is a useful skill, but sometimes, professional help is the best option.

Conclusion: Mastering the Art of Headless Screw Removal

Dealing with a screw with no head can be a frustrating experience, but it doesn’t have to derail your project. By understanding the causes of screw breakage and mastering these techniques on how to remove a screw with no head without an extractor, you can confidently tackle this common DIY challenge. Remember to always prioritize safety and use the appropriate tools for the job. With a little patience and perseverance, you can conquer even the most stubborn headless screw and get back to enjoying your project. And remember, prevention is always better than cure! By following the tips outlined in this guide, you can minimize the risk of future screw head casualties and keep your projects running smoothly. Now go forth and conquer those stripped screws!